Nominal Composition: Cu 59.0-62.0, Zn 36.7-40.0, Sn 0.5-1.0, Pb 0.20, Fe 0.ITG SUBJECT: TIN WHISKERS - PROBLEMS, CAUSES, AND SOLUTIONS Larger View of Micrograph Largest View of Micrograph

The Largest View images range in size from 125K to almost 500K. The Larger View images range in size from 11K to 120K depending on the image. NOTE: The file size of the Larger and Largest View of the Micrographs are substantially larger than the thumbnail shown.

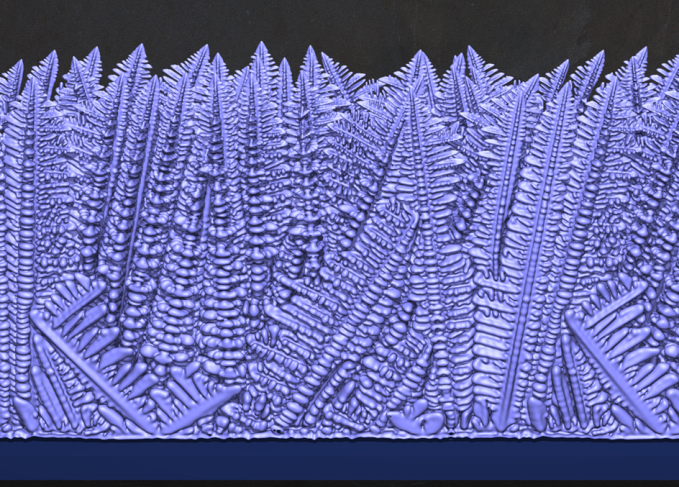

The wrought structure consists of grains of alpha solid solution and grains of zinc and tin rich alpha and delta phases.

#Tin dendrite plus

The tin rich phase transforms to alpha plus delta, which fills the areas between the alpha dendrite arms.

The formation of zinc rich and tin rich beta occurs during solidification. These alloys have a wide freezing range and segregation of the alloying elements occurs during solidification. While the semi red cast brasses have up to 17% zinc and less than 6% tin. The cast red brasses have less than 12% zinc and less than 7% tin. The wrought microstructure contains twinned grains of alpha copper solid solution and beta grains. Alloys with higher zinc contents have multi phase structures, made up of alpha and beta. The wrought microstructure contains twinned grains of alpha solid solution. The cast structures contain cored dendrites, the zinc and tin content of the dendrites increasing from the center to the edge of the dendrites. The structure consists of alpha copper solid solution containing zinc and tin. Tin brasses with low zinc and low tin contents are single phase alloys. The microstructure of the tin brasses is dependent on the zinc and tin content of the alloy. The cast red brasses are labeled UNS C83300 through C83810 and the cast semi red brasses are UNS C84200 through C84800. The wrought tin brasses are designated by UNS C40400 through C48600. Cast red brasses are also made containing lead which increases their machinability and pressure tightness. These materials have moderate strength, high atmospheric and aqueous corrosion resistance, and excellent electrical conductivity. They have reduced corrosion resistance, but retain their good strength. Semi red brasses contain up to 15% zinc and are lighter in color than the red brasses. Alloys that contain less than 8% zinc are a red copper like color, and hence the name red brass. The cast tin brasses are called cast red brasses.

#Tin dendrite free

This category of brasses includes admiralty brasses, naval brasses and free machining tin brasses. The tin brasses are used in applications such as high strength fasteners, electrical connectors, springs, corrosion resistant mechanical products, marine hardware, pump shafts, and corrosion resistant screw machine parts. They have good hot forgeability and reasonably good cold formability. The tin brasses are economical and have slightly better properties than the straight brasses. Arsenic, antimony and phosphorus also reduce the susceptibility of brasses to dezincification. Dezincification is the selective leaching of zinc from the brass leaving a porous copper structure. Tin reduces susceptibility of the high zinc brass to dezincification. This family of alloys is made with zinc contents ranging form 2 to 40% zinc, and 0.2 to 3.0% tin. Tin brass is used for its increased corrosion resistance and somewhat higher strength than straight brass.

0 kommentar(er)

0 kommentar(er)